We are involved in offering a remarkable selection of stainless steel collar317 to our valuable clients. They are available in various size according to customer demand. STAINLESS 317 Collar Buttweld Fittings, STAINLESS 317Collar Buttweld Fittings Pipe Fittings, STAINLESS Stainless Steel 317 Collar Buttweld Fittings, Steel Stainless Steel 317 Collar Buttweld Fittings Pipe Fittings, etc in different estimations to meet up the shifting necessities of grouped endeavors. Exceptional emphasis can be laid on the thought of these Stainless Steel 317 Collar Buttweld Fittings and along these lines, we execute stringent quality control philosophy that conforms to Worldwide Standards. These Stainless Steel 317 Collar Buttweld Fittings are made using ensured metal acquired from solid suppliers. STAINLESS 317 Collar Buttweld Fittings that are offered in different conclusions. The number we offer consolidates STAINLESS Stainless Steel 317 Collar Buttweld Fittings, Carbon Steel Socketweld Fittings, and Alloy Steel Socketweld Fittings. These are delivered making use of assessed materials to meet up the customer”s wants and requirements. Our things are notable for their high flexibility, bother free make use of and strength.

· Setscrew shaft collar for applications assisting low axial loads and basic positioning

· Effective on shafts made of softer material than the setscrew material

· Stainless metal 303 for greater corrosion resistance than steel or aluminum

· Includes a forged setscrew for securing the collar onto the shaft

· Operating temperatures range between -40 to 176 degrees C (-40 to 350 degrees F)

· This Ruland setscrew shaft collar is made of stainless steel 303. It really is a setscrew-type shaft collar for applications supporting low axial loads and basic positioning. Setscrew collars have improved keeping power when the shaft materials is softer compared to the setscrew material. It is made of stainless 303 for greater resistance to corrosion than metal or aluminum. This collar comes with a forged setscrew for securing the collar onto the shaft. The operating temperatures for this collar range from -40 to 176 degrees C (-40 to 350 degrees F). This shaft collar is ideal for use in a variety of applications, including in the automotive industry to situate components in vehicle power steering assemblies, the production industry to locate components on a conveyor belt system, and the hobby craft Stainless Collar sector to hold wheels on axles in remote control vehicles, among others.

·

· Shaft collars are ring-shaped devices mainly used to secure parts onto shafts. In addition they provide as locators, mechanical stops, and spacers between various other components. The two simple types of shaft collars are clamping (or split) collars, that can come in one- or two-piece styles, and setscrew collars. In both types, a number of screws contain the collars in place on the shaft. In setscrew collars, screws are tightened through the collar until they press straight against the shaft, and in clamping collars, screws are tightened to uniformly compress the collar around the shaft without impinging or marring it. Setscrew collars and one-piece clamping collars should be installed by sliding the collar over the finish of the shaft, while two-piece clamping collars individual into two halves and will be installed between components on the shaft. Shaft collars are produced from an array of materials including zinc-plated steel, light weight aluminum, nylon, and neoprene. Within nearly every type of machinery and sector, shaft collars are found in applications including gearbox assemblies, motor bases, machine tools, drive shafts, agricultural implements, medical apparatus, and paper and metal mill equipment, amongst others.

·

· Ruland manufactures shaft collars, rigid couplings, and zero-backlash movement control couplings including beam couplings, bellows couplings, Oldham couplings, curved jaw couplings, and miniature disc couplings. The company, founded in 1937, and headquartered in Marlborough, MA, complies with Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization, and Restriction of Chemical substances (REACH) standards.

· LCM-8-SS Stainless Steel Double Split Shaft Collar 8mm (8x18x9)

·

· Stainless Metal for corrosion resistance complete with stainless steel screws.

·

· Our selection of shaft collars certainly are a cost effective solution to positioning parts or offering a stop placement on a shaft.

·

· Dual split (2 piece) collars are suited to applications where you are struggling to slide the collar on from the end of the shaft. They could be situated in between existing items saving enough time of dismantling the complete shaft.

Split Clamping Collars Stainless Steel, or Stainless Steel Split Arranged Collars, can be utilized as end stops, for fixing elements or clamping. These Stainless Clamping Collars are 303 stainless steel with stainless grub screws. Precision clamping collars eliminate risk of damage to the shaft surface, also during high clamping forces.

Simple set up and adjustment

Clamp grips shaft without departing score marks

Stainless steel for extra corrosion resistance

Hugs the shaft with all round grip

Effective on hardened or plain shafts

Clamp-style and set screw shaft collars from Grainger can be indispensable to power transmission. They are able to keep bearings and sprockets on shafts, situate elements in engine and gearbox assemblies and serve as mechanical stops. A two-piece clamping shaft collar can certainly wrap around a hard or soft shaft without marring. Set screw collars use a cup stage socket set screw to lock onto a gentle or predrilled shaft.

Allows assembly / disassembly on and off the shaft without the need to remove other ancillary parts. Clamps firmly in place once tightened to the shaft. Ideal for positioning parts such as for example bearings or sprockets onto shafts.

§ Manufactured with plain finish maintaining bore size: 7/16″, outside diameter: 15/16″ and width: 3/8″.

§ Best suited for shafting applications that require greater axial load capability.

§ Stainless steel construction helps it endure cleaning with detergents and large wash-downs using industrial cleaning solutions.

§ Perfect for make use of in food processing, medical, and pharmaceutical industries.

§ Fabricated with a shiny polished complete for added safety when used in the toughest environmental conditions.

§ Designed to wrap around the shaft for even distribution of clamping forces.

§ It is definitely stamped with bore size, which helps in easy identification during maintenance and substitute.

§ Precision engineered to ensure a tight fit

§ Superior fit, complete, and remarkable holding power.

§ Safely secure elements onto a shaft.

§ Produced with collar width: 5/16″, bore diameter: 5/16″ and outside  diameter: 11/16″.

diameter: 11/16″.

§ Ideal for use in rugged conditions of construction, refinery, production, and automotive industries.

§ Possesses exceptional holding power, making it ideal for use with hard and soft shafts.

§ Easy to put together and disassemble.

§ Recognized in the worldwide market due to its ability to distribute power uniformly and consistently around the circumference of the shaft.

§ Performance is certainly unaffected when in touch with hydrocarbon solutions.

Climax Part C-150-S Set Screw Collar is manufactured with T303 STAINLESS, which is effective in corrosive environments. Sizes are 1-1/2 ID, 2-1/4 in. OD, 3/4 in. Width. It is effective on hard and soft shafts. It is a Cost effective collar design and quickly installed where major disassembly would otherwise be required.

· Effective on hard and soft shafts

· Cost effective collar design

· Easily installed where major disassembly would otherwise be required

· T316 stainless is highly effective in corrosive environments

With contact spread over the whole tooth the spiral bevel gear can be run much quicker than the straight tooth bevel equipment and handle harder begins and stops.

With contact spread over the whole tooth the spiral bevel gear can be run much quicker than the straight tooth bevel equipment and handle harder begins and stops. worm equipment sets) are right angled drives and are used in screw jacks where the input shaft reaches right angles to the lifting screw. Other kinds of right position drives are bevel gears, and hypoid gears. Worm drives satisfy the requirements of many systems and offer a compact means of decreasing velocity whilst raising torque and so are therefore ideal for use in systems utilising e.g. lifting equipment where a high gear ratio implies it could be driven by a small motor.

worm equipment sets) are right angled drives and are used in screw jacks where the input shaft reaches right angles to the lifting screw. Other kinds of right position drives are bevel gears, and hypoid gears. Worm drives satisfy the requirements of many systems and offer a compact means of decreasing velocity whilst raising torque and so are therefore ideal for use in systems utilising e.g. lifting equipment where a high gear ratio implies it could be driven by a small motor. Therefore, the same gear cannot be meshed together, and it is required to pair the proper and remaining handed pairs.

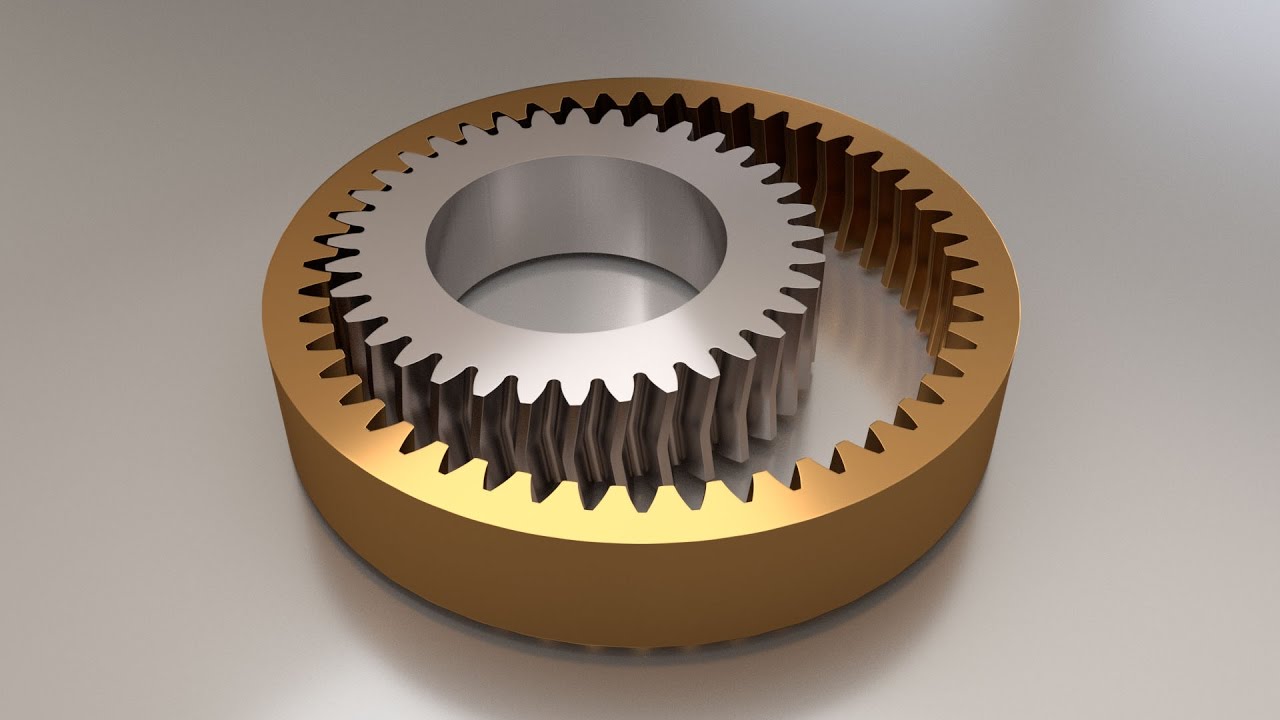

Therefore, the same gear cannot be meshed together, and it is required to pair the proper and remaining handed pairs. in the internal surface of a cylinder and meshes with spur gears.

in the internal surface of a cylinder and meshes with spur gears. and

and  and divert torque during acceleration to the within wheel, which it perceives as having more hold.

and divert torque during acceleration to the within wheel, which it perceives as having more hold. changes in shaft alignment because of operating conditions. These types of gear couplings are generally limited to angular misalignments of 1/4 to 1/2°.

changes in shaft alignment because of operating conditions. These types of gear couplings are generally limited to angular misalignments of 1/4 to 1/2°. diameter: 11/16″.

diameter: 11/16″.