China Custom Mechanical Parts – CNC Machining & Power Transmission for Agricultural Machinery

Product Description

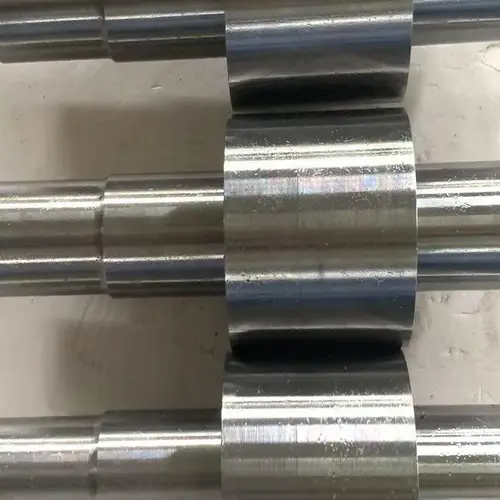

Discover high-quality, precision-engineered mechanical parts for a myriad of applications, including agricultural machinery, automotive, and industrial sectors. Our extensive range of products includes starter components, CNC machined parts, drive gears, power transmission shafts, and PTO (Power Take-Off) shafts. Crafted from durable steel and tested rigorously for reliability and performance, our products meet the highest standards of quality and efficiency.

Quality Assurance

Our quality-focused approach ensures that each product undergoes meticulous inspection and testing before delivery. Certified under ISO9001 and IATF16949 standards, we guarantee the best performance and durability for our customers.

| Certification | Shipment | Quality | Material | Company System Certification |

|---|---|---|---|---|

| IATF16949 | On-time | High | Steel | ISO9001 |

Certifications

Our commitment to excellence is highlighted by our certifications. We ensure that each product is designed and manufactured to meet international standards. Certifications include:

- IATF16949

- ISO9001

Frequently Asked Questions (FAQ)

Q1: How is the quality of your product?

A: Our products boast reliable quality and high wear life.

Q2: What is your customization process?

A: Our process includes Advisory – Material selection – 2D/3D Drawing – Quotation – Payment – Production – Quality Control – Package – Delivery.

Q3: What is your terms of packing?

A: Generally, we pack our goods in wooden cases. If you have special packing requests, please negotiate with us in advance.

Q4: What are your terms of payment?

A: 30% T/T in advance, 70% T/T before shipping.

Q5: Do you test all your goods before delivery?

A: Yes, we perform a 100% test before delivery to ensure product quality.

Additional Product Lines

Our portfolio extends beyond precision mechanical parts. EVER-POWER GROUP supplies a broad range of industrial products, including agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, and bushings. We pride ourselves on offering high-quality products at competitive prices, complemented by our exceptional customer service. We welcome customers to customize products based on their drawings and samples.

Understanding the Performance Characteristics of PTO Drive Shafts

PTO drive shafts, or power take-off shafts, are crucial components in various machinery. Their performance characteristics include:

High Efficiency

PTO drive shafts are designed to transfer power efficiently from tractors to attached implements, reducing energy loss and optimizing performance.

Durability

Constructed from high-strength materials, these shafts can withstand extreme working conditions and heavy loads, ensuring longevity and reliability.

Versatility

They are adaptable to different types of machinery, making them a versatile solution for powering a wide range of equipment.

Safety Features

Modern PTO drive shafts are equipped with various safety features, including protective guards and shear pins, to prevent accidents and equipment damage.

Types and Characteristics of PTO Drive Shafts

PTO drive shafts come in different types, each with unique characteristics:

Telescoping Shafts

These shafts can adjust in length, making them suitable for equipment that requires flexibility in movement.

Non-Telescoping Shafts

Rigid and sturdy, these shafts are ideal for applications where a fixed length is necessary.

Material Advantages of PTO Drive Shafts

Steel PTO Drive Shafts

Known for their high strength and durability, steel shafts are suitable for heavy-duty applications.

Aluminum PTO Drive Shafts

Lighter than steel, aluminum shafts offer good strength-to-weight ratio and are resistant to corrosion, making them ideal for marine applications.

Composite PTO Drive Shafts

Combining the best properties of various materials, composite shafts provide excellent performance in terms of weight, strength, and durability.

Applications of PTO Drive Shafts in Various Fields

Agricultural Machinery

PTO drive shafts are essential in tractors and other farming equipment, enabling efficient power transfer to machinery like harvesters and plows.

Construction Equipment

In construction, PTO shafts power equipment such as concrete mixers and bulldozers, ensuring robust performance in demanding environments.

Industrial Equipment

Industries rely on PTO shafts for machinery like conveyor belts and compressors, facilitating smooth and efficient operations.

Marine Equipment

For marine applications, PTO shafts drive pumps and winches, proving their versatility and reliability in harsh maritime conditions.

Forestry Equipment

In forestry, these shafts power equipment such as wood chippers and log splitters, enhancing productivity and operational efficiency.

Future Development Trends and Opportunities in PTO Drive Shafts

The future of PTO drive shafts looks promising with advancements in technology and materials. Key development trends and opportunities include:

Advanced Materials

The use of advanced materials like carbon fiber composites can significantly reduce weight while maintaining strength, leading to more efficient and durable drive shafts.

Enhanced Safety Features

Innovations in safety features, such as automatic disengagement systems, can further reduce the risk of accidents and equipment damage.

Smart Technology Integration

Integrating smart technology into PTO drive shafts can enable real-time monitoring of performance and condition, allowing for predictive maintenance and reducing downtime.

Eco-Friendly Designs

Developing eco-friendly PTO drive shafts that minimize energy consumption and environmental impact can meet the growing demand for sustainable solutions.

How to Choose a Suitable PTO Drive Shaft

Selecting the right PTO drive shaft involves considering several factors:

Identify the Application

Determine the specific machinery and tasks the PTO shaft will be used for to ensure compatibility and performance.

Assess Power Requirements

Evaluate the power needs of your equipment to choose a shaft that can handle the required load and operate efficiently.

Check Speed and Torque Specifications

Ensure the PTO drive shaft matches the speed and torque specifications of your machinery to avoid performance issues and potential damage.

Evaluate Connection Types

Consider the type of connections required, such as splined or smooth shafts, to ensure a secure and efficient fit.

Inspect Safety Features

Look for PTO shafts with robust safety features like guards and shear pins to protect both operators and equipment.

Material and Construction

Choose a PTO drive shaft made from materials that can withstand the working conditions and demands of your specific application.

Conclusion

PTO drive shafts are versatile and essential components in various industries, from agriculture to marine applications. Understanding their performance characteristics, types, and material advantages can help you select the best shaft for your needs. As technology advances, the future of PTO drive shafts looks promising, with opportunities for enhanced safety, efficiency, and sustainability. By considering factors like application, power requirements, and safety features, you can ensure you choose a suitable PTO drive shaft that meets your operational demands.

Author: Dream