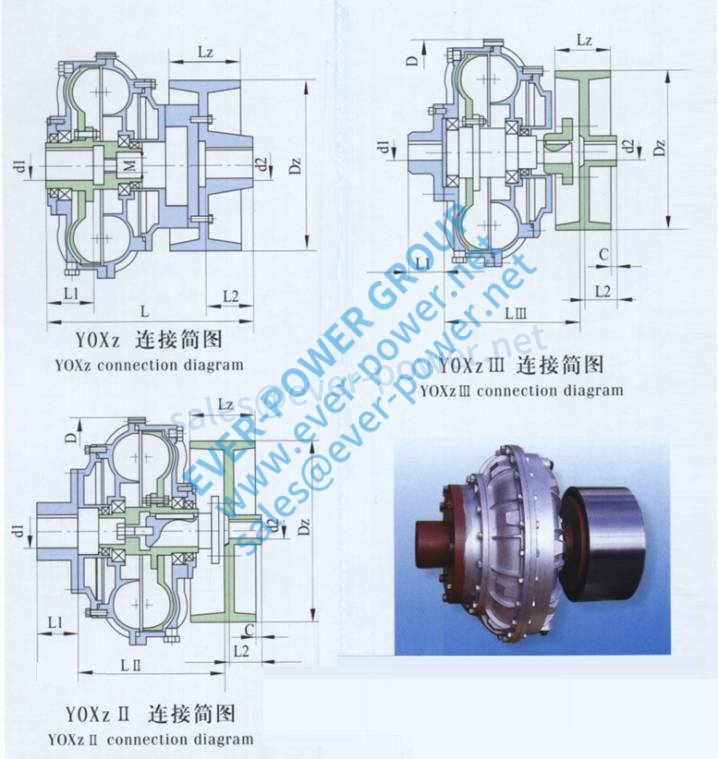

fluid coupling

Economical soft commences, with smooth acceleration

Shock-  load defense

load defense

Fluid Couplings

Kind HF25 Disc Coupling Mount

From underground & overland belt conveyors to crusher and mixing programs, gear professionals are continuously in search of greater technologies to safeguard essential manufacturing techniques towards the consequences of damaging shock masses. And when it comes to getting rid of sudden/ jarring commences, or preventing program failure/ deterioration because of to overloads, nothing at all outperforms the program- conserving capacity of Falk True Torque fluid couplings.

Unmatched, cushioned gentle start flexibility, at an affordable price tag point.

Clean acceleration.

Mechanical overload protection.

NEW measurements 2760HF & 2870HF offer greater ability at greater speeds.

Elevated starting torque obtainable from normal NEMA B motors

with a fluid coupling. This is a gain not supplied by digital comfortable start off solutions.

Supplying the softest, smoothest begin will improve the daily life of your system parts.

As the smart different to expensive & difficult digital solutions, Falk Accurate Torque⢠fluid couplings allow specific adjustment of startup qualities in the discipline, just by modifying the fluid fill degree by way of the simple access fill & drain holes.

fluid coupling cross-segment

NEW For a longer time starting up profiles and  softer starts.

softer starts.

For Sizes 1420HF & bigger, adjustable metering orifices control the passage of fluid from the hold off fill chamber into the working circuit, additional softening the commence.

For sophisticated belt conveyors, think about Kind HFDD. The extended hold off fill chamber permits original start off issue as low as forty% of the total load torque, substantially decreasing shock & extend to the belt at startup.

fluid coupling cross-area

Use of the prolonged hold off fill chamber (HFDD) is recommended for conveyors subjected to unloaded starts off, these with concave sections, individuals with reduced inertia, or those with any mix of these problems. Modest fill in the operating circuit at startup minimizes belt liftoff, and assures unloaded & lower inertia conveyors are not speedily accelerated. Protection â irrespective of load issue.