What is pin bush coupling?

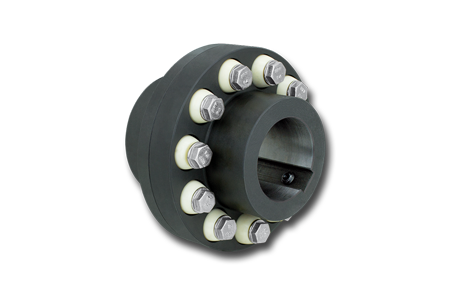

Industrial Pin Bush Coupling

The function of a flexible coupling is to transmit torque from on shaft to another where limited mis alignment might occur and to absorb shock loads.

We are among the prominent institutions engaged in providing Pinbush Coupling which has highly developed rubber compounds for use in bushes to absorb shock, tensional vibrations and slight misalignments. These couplings will be flexible in type and tend to be of the cushioned travel type that is utilized for transmitting the torque through maximum tensile steel bolts to the machine input. Moreover, they are simple and compact in construction that makes these capable of transmitting huge torques at maximum speeds. These kind of couplings generally permit travel in either path and require neither lubrication, nor adjustment after fitting.

Pin and Bush Couplings

lubrication-free

Features

Vertical/horizontal mounting

Adsorbs vibrations

Progressive torsion early spring properties due to primarily pressurised bushings

Fail-safe in case of the failure of the bushings

Convenient replacement of bushings without disassembly of the coupling halves

Free of maintenance, no lubrication necessary

Declaration of conformity in accordance with ATEX 2014/34/EU possible

Typical applications

Pump drives

Belt drives

Ventilators

General mechanical engineering

Ever-vitality pin and bush coupling

Ever-power couplings consist of a set of resilient BARREL Shaped bushes with pins & nuts and two flanged hubs of graded cast iron.

The special BARREL shaped bushes permit the MISALIGNMENT IN ALL DIRECTIONS and present extra torsional flexibility as compared to plain bushes.

These couplings are ideal for basic engineering application requiring reliable power tranny even underneath conditions of shaft misalignments which are generally unavoidable.

Description

Ever-power couplings are used since flexible compensating couplings in all applications requiring a trusted transmission of torque under harsh operating circumstances. The conical chairs of the buffer pins facilitate installation and guarantee maintenance-free operation. The optimized form of the barrelled buffers permits straightforward plug-in assembly and low circumferential backlash. Various type variants are offered, e. g. with brake disk, axial play limiting gadget, or brake motor couplings.

To the top of the page  Examples of application

Examples of application

Ever-power couplings are being used in general mechanical engineering both because high-acceleration couplings and for high torques, e. g. in

Cranes

Conveyors

Blowers

Screw pumps

Cableways

Mixers

Cement processing machines7

To the top of the page

Advantages of the product

Flexible fail-safe pin and bush coupling for medium up to high torques

Compact design; low weights and mass occasions of inertia

Independent of direction of rotation (ideal for reversing operation)

Ideal for plug-in assembly (blind assembly, bell housing installation)

Torque range of the standard series between 200 Nm and 1,300,000 Nm

Can be used in potentially explosive atmospheres; certified acc. to 94/9/EC (ATEX 95)

Pin & Bush Couplings

Simple and practically indestructible, the pin and bush design is perfect for applications that involve basic safety, such as elevator drives or fire pumps. The fail-safe aspect of the design allows the coupling to end up being serviced at effortless intervals, if the elastomer become damaged.

The elastomer elements decrease vibration and dampen impact loads, together with accommodate misalignment up to 0.5 degrees. The original bushing is normally a neoprene elastomer with a graphite impregnated bronze sleeve. These are still available, as well as a contemporary version of this concept: urethane bushings.

Ever-electrical power also manufactures many custom variations of this coupling including brake drum and shear pin type couplings.

Damping shaft coupling that can be utilized universally to pay for shaft misalignment

Nominal torque range between TKN = 19 Nm up to 62,000 Nm with 23 sizes

Temperature range: from -50 °C to +100 °C

Robust and verified a million times

Because of their torsional overall flexibility, Ever-power couplings can approach critical torsional vibrations away from the operating region of mechanical equipment so that no unwanted effects on the travel train are to be expected. Ever-power couplings are created from high-top quality cast iron. The versatile elements manufactured from synthetic rubber (Buna-N) are available in different degrees of hardness for most applications. Metallic pins and flexible components are designed to ensure that no use occurs if they are properly fitted.

Your benefits at a glance

Fail-safe for maximum operational reliability

Three-part type ideal for plug-in assembly and simplified replacing of elements

Choice of elastomer hardness to suit various applications

Suitable for use in potentially explosive environments; certified according to

2014/34/EU (ATEX)

High degree of availability of parts ex stock

Established as an commercial standard, worldwide in use

Mining and Cement: heat technology

Oil and Gas: pumps, fans, compressors, air condensers

Power Generation: pumps, lovers, compressors, air condensers, drinking water turbines

Chemical substances and Pharmaceuticals: driers, lauter tuns, pumps, lovers, compressors, mixers, agitators, reactors

Plastic and Rubber: sole- and double-screw extruders

Pulp and Paper: wastewater purification plants

Water and Wastewater: aerators

Meals and Beverage: lauter tuns, reactors, agitators, mixers

Did you know?

Original Ever-power elastomers ensure the perfect operation of one’s body. The flexible components of the Ever-electricity coupling are subject to compression. If the flexible elements are irreparably ruined, the hub parts come into contact with metal. This “emergency operation capability” is necessary, e.g., in the case of fire pump drives.